Our premium chromium sputtering target is what you need! This top-quality target provides consistent and reliable results, minimizing downtime and ensuring optimal performance in your sputtering process.

Chromium is a versatile metal with a wide range of applications, making it a popular choice for sputtering targets used in various thin film coating processes. A chromium sputtering target is a key component in physical vapor deposition (PVD) and pulsed laser deposition (PLD) systems, where a thin film of chromium is deposited onto a substrate to achieve specific properties or functions.

One of the primary applications of chromium sputtering targets is in tooling coating. Coating tools with a layer of chromium can enhance their durability, hardness, and wear resistance, making them more effective for cutting, drilling, and machining operations. Chromium coatings can also improve the tool's resistance to corrosion and chemical degradation, prolonging its service life and reducing maintenance costs.

In addition to tooling coating, chromium sputtering targets are commonly used in decorative coating applications. The unique metallic luster and corrosion resistance of chromium make it an ideal choice for creating decorative finishes on a wide range of products, from consumer electronics and automotive parts to jewelry and architectural elements. Chromium coatings can be applied in varying thicknesses to achieve different aesthetic effects, such as high-gloss or matte finishes, adding value and visual appeal to the coated surfaces.

Chromium sputtering targets are also utilized in thin film coating processes for functional applications, such as optical coatings, electrical conductive layers, and barrier coatings. Chromium thin films exhibit excellent optical properties, including high reflectivity and low emissivity, making them suitable for antireflection coatings on optical lenses, mirrors, and displays. Furthermore, chromium coatings provide good electrical conductivity and thermal stability, making them ideal for applications in microelectronics, sensors, and solar cells.

The quality and performance of a chromium sputtering target are critical to the success of thin film coating processes. Superior purity, uniformity, and density of the chromium target material are essential for achieving consistent and reproducible coating properties. Advanced manufacturing techniques, such as hot isostatic pressing (HIP) and powder metallurgy, ensure the production of high-quality chromium sputtering targets with minimal impurities and defects.

When selecting a chromium sputtering target for your coating application, it is essential to consider factors such as target size, shape, and composition to meet your specific requirements. Customized designs, such as circular, rectangular, or rotary targets, are available to fit different sputtering systems and deposition configurations. High-purity chromium targets with a purity level of 99.95% are recommended for critical thin film coating applications that demand ultra-low levels of contaminants.

In conclusion, chromium sputtering targets are essential components in PVD and PLD systems for coating tooling, decorative, and functional applications. With their exceptional properties and performance, chromium coatings offer a versatile and reliable solution for enhancing the durability, aesthetics, and functionality of a wide range of products. Investing in high-quality chromium sputtering targets ensures the successful deposition of thin films with superior quality and performance, delivering value and innovation to your coating processes.

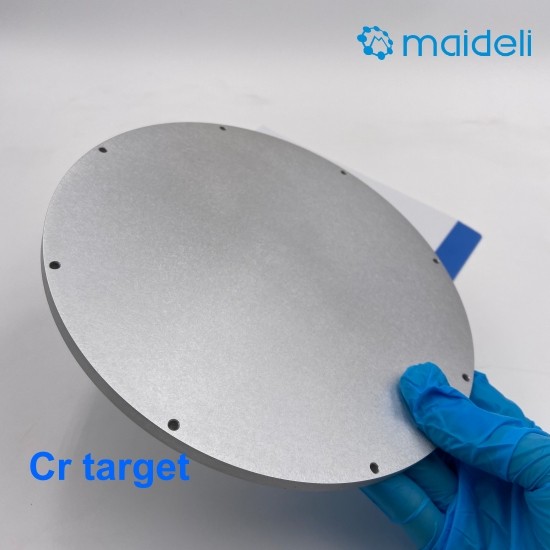

Chrome Sputtering Target

Manufacturing Process : Hot Isostatic Pressing

Chemical formula : Cr

Melting Point : ℃

Density:7.14g.cm3

Specification : Max 4000mm,OD:<=300mm ; Or as customers' requirements .

Purity : 99.5% ,99.7%,99.8%,99.9%,99.95%

Grain Size <50um

Features:

- Made from high-quality chromium material for superior performance

- Provides consistent and reliable results

- Minimizes downtime for maximum efficiency

- Ideal for achieving goals in sputtering technology

Applicable Groups:

- Engineers and researchers working in sputtering technology

- Companies operating in the semiconductor, solar panel, and LCD industries

Applicable Scenarios:

- Sputtering process in the semiconductor industry

- PVD (physical vapor deposition) in the solar panel and LCD industries

Cr Rotary Target

| Manufacturing Process | Sprayed | HIP |

| Content | Chromium | Chromium |

| Purity | 99.5%~99.8% | 99.5%~99.95% |

| Relative Density | >95.0% | >99.0% |

| Grain Size | <100um | <50um |

| Type | Rotary | Rotary and Planar and Arc |

| Dimension | Max Length 2000mm,Max Thickness 6mm | OD≤300 Max Length 2000mm |

Process Comparsion between Spray Cr rotary target and HIP Cr rotary Target

| Spray Cr target | HIP Cr Target | |

| Oxygen Content | 8000ppm | 80ppm |

| Relative Density | ≥95% | ≥98% |

| Purity | 99.5 | 99.5%~99.95% |

| Grain Size | ≤100um | <50um |

| Uniformity | a) larger difference at axial densityb) The uniformity of the target can’t be guaranteed | a)High uniformity of the whole target b)Density is close to the extrusion density of pure metal ,the rotary target has a uniform density c)No loose zone d)No dark zone e)High uniformity at the sputtering material at top ,middle and bottom part f)High uniformity at the thickness and color of the PVD coating g)Nigh uniformity of the L、a、b at the top,middle and bottom part . |

| PVD Current Density | Can’t reach long working hours at large current | Long working hours under high-power |

Please send us your request with below details to " sales@mdlmaterials.com"

1. Size /Tolerance ( or drawing )

2. Purity

3. Quantity