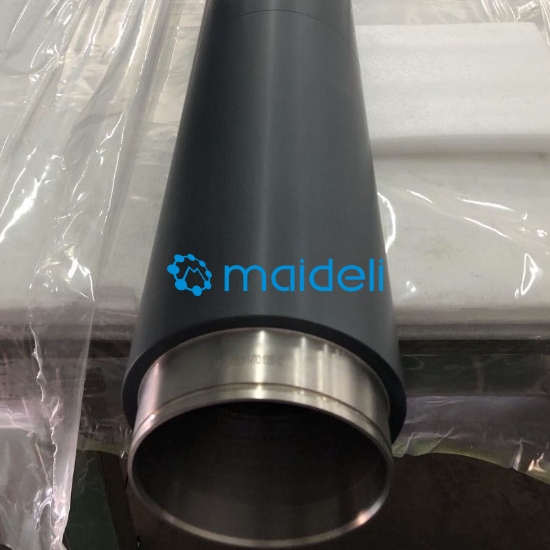

Chemical formula : In2O3/SnO2 Appearance : Black lump ceramic target

Product Name: Premium Indium Tin Oxide Sputtering Targets

Introduction:

At our website, we offer premium Indium Tin Oxide Sputtering Targets that are designed to ensure precision and efficiency in your sputtering process. Our products are crafted to meet your specific requirements, and we guarantee that you will experience the difference our products can make.

Product Features:

- High-quality Indium Tin Oxide

- Excellent sputtering performance

- Superior target purity and density

- Customizable sizes and shapes

- Long-lasting durability

Applicable Groups:

- Research institutes

- Semiconductor manufacturers

- Solar cell manufacturers

- Electronic component manufacturers

Applicable Scenarios:

- Fabrication of transparent conductive films

- Optical coatings

- Electrode deposition

- Thin-film transistors

- LCD displays

Cost Performance:

Our Indium Tin Oxide Sputtering Targets offer excellent cost performance, due to their long-lasting durability and high sputtering performance, leading to less material waste and reduced downtime.

In summary, our premium Indium Tin Oxide Sputtering Targets are a reliable and cost-effective choice for your sputtering needs. Customizable to your specific requirements, they offer exceptional performance and durability, making them ideal for a wide range of applications in research, semiconductor, solar cell, and electronic component manufacturing. Order now and experience the difference that our products can make in your projects' success.

Indium Tin Oxide (ITO) sputtering targets are widely used in the thin film coating industry due to their unique properties that make them ideal for applications in electronics, optics, and other high-tech applications.

ITO is a transparent conductive oxide material that is composed of a combination of indium oxide and tin oxide. This unique combination of materials gives ITO sputtering targets their excellent conductivity and transparency, making them ideal for use in applications where both of these qualities are required.

One of the key applications of ITO sputtering targets is in the production of transparent conductive coatings for electronic displays, such as LCD screens, touch screens, and solar panels. The high transparency of ITO allows for maximum light transmission through the coating, while its excellent conductivity ensures that electric current can flow efficiently through the material. This makes ITO sputtering targets an essential component in the production of high-quality electronic displays that require both transparency and conductivity.

In addition to electronic displays, ITO sputtering targets are also used in a variety of other applications, such as in the production of anti-reflection coatings for optical lenses, windows, and mirrors. The transparency of ITO allows for maximum light transmission through the coating, while its conductivity helps to reduce glare and improve the overall optical performance of the coated surface. This makes ITO sputtering targets a popular choice for use in a wide range of optical applications where both transparency and conductivity are key requirements.

Another important application of ITO sputtering targets is in the production of thin film solar cells. The high transparency of ITO allows for maximum light absorption in the solar cell, while its excellent conductivity helps to efficiently transport the generated electrical current out of the cell. This makes ITO sputtering targets an essential component in the production of high-efficiency thin film solar cells that require both transparency and conductivity to operate effectively.

Overall, ITO sputtering targets are a versatile and essential material in the thin film coating industry, with a wide range of applications in electronics, optics, and other high-tech fields. Their unique combination of transparency and conductivity make them ideal for use in a variety of applications where these qualities are required, making them a popular choice for manufacturers looking to produce high-quality thin film coatings for a range of different products.

ITO Production process diagram

1. Main application:

ITO conducting glass

ITO thin film

2.Product Characteristics

2.1 .Chemical formula : In2O3/SnO2

2.2 .Appearance : Black lump ceramic target

2.3 .Purity: ≥99.99%

(Al,Fe,Cu,Ni,Pbamount ≤80ppm)

2.4 .Grain size : 5~15um

2.5. Relative density : ≥99.5%

2.6. Electrical resistivity: <1.2*10-4Ω▪cm

2.7. Thermal coefficient of expansion : 5.8*10-6 K-1

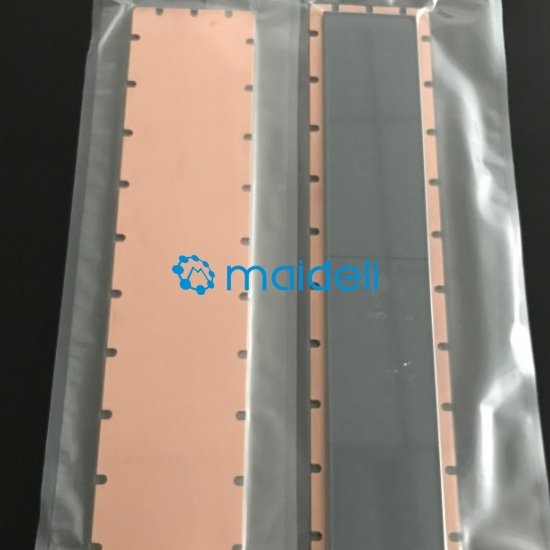

Shape :Disc,Rectangle

Currently our standard round target sizes range from 1" to 20" in diameter, and the rectangular targets are available in lengths up to and over 2000mm in single or multiple piece construction depending on the metal.

Please send us your request with below details to " sales@mdlmaterials.com"

1. Size /Tolerance ( or drawing )

2. Purity

3. Quantity